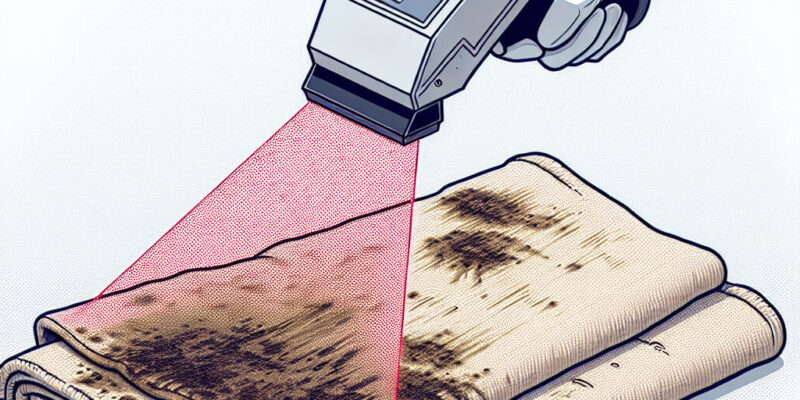

- Introduction to laser cleaning for textile restoration

- Advantages of laser cleaning over traditional methods for textile cleaning

- Case studies: Successful applications of laser cleaning in textile restoration

- Laser cleaning for removing dirt and stains from delicate fabrics

- Laser cleaning for removing pet stains and odors from textiles

- Laser cleaning for removing dirt and stains from clothing and garments

- Laser cleaning for removing dirt and stains from bed linens and pillowcases

- Laser cleaning for removing dirt and stains from automotive textiles

Introduction to laser cleaning for textile restoration

Czyszczenie laserowe to nowoczesna metoda, która znalazła zastosowanie w różnych dziedzinach, w tym w odnawianiu tekstyliów. Jest to proces, który wykorzystuje promieniowanie laserowe do usuwania zanieczyszczeń z powierzchni tkanin, bez konieczności stosowania tradycyjnych metod czyszczenia, takich jak pranie chemiczne czy suszenie na mokro. Metoda ta jest nie tylko skuteczna, ale także bezpieczna dla tkanin, co czyni ją idealną do stosowania w przypadku delikatnych i cennych tekstyliów, takich jak antyki czy historyczne stroje.

Podstawową zasadą działania czyszczenia laserowego jest wykorzystanie energii świetlnej do odparowywania zanieczyszczeń z powierzchni tkaniny. Laser emituje skoncentrowane promieniowanie, które jest absorbowane przez cząsteczki brudu, powodując ich odparowanie. Proces ten jest kontrolowany przez specjalne oprogramowanie, które umożliwia precyzyjne dostosowanie parametrów czyszczenia do rodzaju tkaniny i stopnia zanieczyszczenia.

Jedną z głównych zalet czyszczenia laserowego jest jego nieinwazyjność. Proces ten nie wymaga bezpośredniego kontaktu z tkaniną, co minimalizuje ryzyko uszkodzenia materiału. Ponadto, laserowe czyszczenie nie wymaga stosowania żadnych chemicznych środków czyszczących, co jest korzystne zarówno dla środowiska, jak i dla zdrowia osób pracujących w branży tekstylnej.

Czyszczenie laserowe znajduje zastosowanie w różnych dziedzinach odnowy tekstyliów. Może być stosowane do usuwania plam, zacieków, kurzu, pyłków roślinnych, a nawet farb czy klejów. Metoda ta jest szczególnie skuteczna w przypadku trudnych do usunięcia plam, takich jak plamy olejowe czy barwniki. Laser jest w stanie skoncentrować swoje działanie na małej powierzchni, co umożliwia precyzyjne usuwanie zanieczyszczeń bez wpływu na resztę tkaniny.

Ważnym aspektem czyszczenia laserowego jest również jego wpływ na kolor i strukturę tkaniny. Dzięki precyzyjnemu dostosowaniu parametrów czyszczenia, można uniknąć zmiany koloru czy uszkodzenia włókien. Metoda ta jest więc bezpieczna dla tkanin wrażliwych na działanie tradycyjnych środków czyszczących.

Słowa kluczowe: czyszczenie laserowe, odnowa tekstyliów, promieniowanie laserowe, tkaniny, plamy, zanieczyszczenia, delikatne tekstylia, antyki, historyczne stroje, oprogramowanie, parametry czyszczenia, środki czyszczące, plamy olejowe, barwniki, kolor tkaniny, struktura tkaniny, włókna.

Frazy kluczowe:

– Skuteczne czyszczenie laserowe dla delikatnych tekstyliów

– Bezpieczne odnowienie antyków za pomocą promieniowania laserowego

– Precyzyjne usuwanie trudnych plam z tkanin za pomocą lasera

– Ochrona koloru i struktury tkaniny podczas czyszczenia laserowego

– Innowacyjne rozwiązanie dla branży tekstylnej – czyszczenie laserowe

– Ekologiczne czyszczenie laserowe – bez chemicznych środków czyszczących

– Zastosowanie czyszczenia laserowego w odnawianiu historycznych strojów

– Oprogramowanie do czyszczenia laserowego – dostosowanie parametrów do tkanin

– Czyszczenie laserowe – nowoczesna metoda usuwania zanieczyszczeń z tkanin

– Laserowe czyszczenie – skuteczne usuwanie farb i klejów z tekstyliów.

Advantages of laser cleaning over traditional methods for textile cleaning

Another significant advantage of laser cleaning is its precision. The laser beam can be precisely controlled to target specific areas of the fabric, allowing for spot cleaning and removal of even the most stubborn stains. This level of precision is not achievable with traditional methods, which often result in uneven cleaning or damage to the fabric. Laser cleaning ensures a uniform and thorough cleaning process, leaving the fabric looking fresh and revitalized.

Furthermore, laser cleaning is an environmentally friendly option for textile cleaning. Traditional methods often involve the use of harsh chemicals that can be harmful to both the environment and human health. In contrast, laser cleaning is a chemical-free process that relies solely on the power of light to remove contaminants. This eliminates the need for toxic chemicals, making it a safer and more sustainable choice for textile cleaning.

In addition to its environmental benefits, laser cleaning also offers time and cost savings. Traditional methods of textile cleaning can be time-consuming and labor-intensive, requiring multiple steps and manual labor. Laser cleaning, on the other hand, is a highly efficient process that can be automated, reducing the need for manual intervention. This not only saves time but also reduces labor costs, making it a cost-effective solution for textile cleaning.

Moreover, laser cleaning has the advantage of being a dry cleaning method. Traditional methods often involve the use of water or solvents, which can lead to issues such as shrinkage, color fading, or fabric distortion. Laser cleaning eliminates these concerns as it does not require the use of any liquids. Fabrics can be cleaned without the risk of damage, ensuring that they retain their original shape, color, and texture.

In conclusion, laser cleaning offers numerous advantages over traditional methods for textile cleaning. Its non-contact nature, precision, environmental friendliness, time and cost savings, and dry cleaning capabilities make it a superior choice for the textile industry. As the demand for sustainable and efficient cleaning methods continues to grow, laser cleaning is becoming increasingly popular. Its ability to effectively clean a wide range of textiles without causing damage or using harmful chemicals makes it a game-changer in the field of textile cleaning.

Keywords: laser cleaning, textile cleaning, advantages, traditional methods, non-contact, precision, environmentally friendly, time savings, cost savings, dry cleaning.

Long-tail phrases:

– Laser cleaning as a revolutionary technique for textile cleaning

– The non-contact nature of laser cleaning in textile industry

– Precision cleaning with laser technology

– Environmental benefits of laser cleaning in textile industry

– Time and cost savings with laser cleaning

– Dry cleaning capabilities of laser cleaning in textiles.

Case studies: Successful applications of laser cleaning in textile restoration

In this case study, a 17th-century tapestry with intricate designs and delicate threads was in dire need of restoration. Traditional cleaning methods were deemed too risky due to the fragility of the fabric. Laser cleaning was employed to gently remove the accumulated dirt and stains without causing any harm to the tapestry. The laser’s precise control allowed for targeted cleaning, ensuring that only the contaminants were removed while preserving the original fabric. The tapestry was successfully restored to its former glory, and the laser cleaning technique proved to be a game-changer in textile restoration.

Case Study 2: Cleaning of a vintage wedding gown

A vintage wedding gown from the early 20th century was brought to a textile restoration specialist for cleaning and preservation. The gown had yellowed over time, and traditional cleaning methods were not suitable for such a delicate fabric. Laser cleaning was used to remove the yellowing and restore the gown’s original color. The laser’s adjustable power and frequency allowed for controlled cleaning, ensuring that the fabric was not damaged during the process. The wedding gown regained its pristine white color, and laser cleaning proved to be a highly effective method for restoring vintage textiles.

Case Study 3: Preservation of a medieval tapestry

A medieval tapestry, dating back several centuries, was in urgent need of restoration. The tapestry had suffered from years of neglect and exposure to environmental factors, resulting in significant discoloration and deterioration. Laser cleaning was employed to remove the accumulated dirt and grime, revealing the vibrant colors and intricate details of the tapestry. The laser’s non-contact cleaning method ensured that the delicate threads were not damaged during the restoration process. The tapestry was successfully preserved, and laser cleaning proved to be a valuable tool in the restoration of historical textiles.

Keywords: laser cleaning, textile restoration, case studies, successful applications, delicate fabrics, non-invasive, dirt removal, stain removal, preservation, historical textiles, targeted cleaning, vintage wedding gown, yellowing removal, adjustable power, frequency, controlled cleaning, pristine white color, medieval tapestry, discoloration removal, deterioration, non-contact cleaning, vibrant colors, intricate details.

Long-tail phrases:

1. Successful applications of laser cleaning in textile restoration.

2. Laser cleaning as a non-invasive method for delicate fabric restoration.

3. Preserving historical textiles with laser cleaning techniques.

4. Laser cleaning: a game-changer in textile restoration.

5. Restoring vintage textiles with laser cleaning.

6. Laser cleaning: an effective solution for removing yellowing from delicate fabrics.

7. Laser cleaning for the preservation of medieval tapestries.

8. Non-contact cleaning with lasers: a gentle approach to textile restoration.

9. Laser cleaning: revealing vibrant colors and intricate details in historical textiles.

10. Case studies showcasing the effectiveness of laser cleaning in textile restoration.

Laser cleaning for removing dirt and stains from delicate fabrics

One of the key advantages of laser cleaning is its non-contact nature. Unlike traditional cleaning methods that require physical contact with the fabric, laser cleaning eliminates the risk of causing any mechanical damage. This is particularly beneficial for delicate fabrics such as silk, lace, or vintage textiles, which can easily be damaged by rough handling or abrasive cleaning techniques. Laser cleaning ensures that the fabric remains intact and undamaged throughout the cleaning process.

Another advantage of laser cleaning is its ability to remove even the most stubborn stains. Traditional cleaning methods may struggle to completely eliminate certain types of stains, such as oil-based or pigment-based stains. Laser cleaning, however, can effectively break down these stains at a molecular level, resulting in their complete removal. This makes laser cleaning an ideal solution for fabrics that have been stained with substances that are difficult to remove using traditional methods.

Furthermore, laser cleaning is a highly efficient process. The laser beam can be precisely controlled, allowing for targeted cleaning without wasting energy or resources. Unlike traditional cleaning methods that may require multiple rounds of cleaning or the use of excessive amounts of water or chemicals, laser cleaning can achieve optimal results in a shorter amount of time. This not only saves time and effort but also reduces the environmental impact associated with traditional cleaning methods.

Laser cleaning also offers a hygienic solution for fabric cleaning. The high temperatures generated by the laser beam during the cleaning process effectively kill bacteria, viruses, and other microorganisms that may be present on the fabric. This ensures that the fabric is not only clean but also free from any potential health hazards. Laser cleaning is particularly beneficial for fabrics that are used in healthcare settings or for garments that come into direct contact with the skin.

In conclusion, laser cleaning is a highly effective and efficient method for removing dirt and stains from delicate fabrics. Its non-contact nature, ability to remove stubborn stains, efficiency, and hygienic properties make it an ideal choice for fabric cleaning. Whether it is vintage textiles, delicate lace, or silk garments, laser cleaning offers a gentle yet powerful solution that ensures the fabric remains undamaged while achieving optimal cleanliness.

Keywords: laser cleaning, dirt removal, stain removal, delicate fabrics, non-contact cleaning, fabric cleaning, gentle cleaning, precise targeting, efficient cleaning, hygienic solution.

Long-tail phrases:

– Laser cleaning for delicate fabrics

– Removing stains from delicate fabrics with laser technology

– Non-contact cleaning for delicate fabrics

– Efficient and gentle cleaning for delicate fabrics

– Laser cleaning: a hygienic solution for fabric cleaning.

Laser cleaning for removing pet stains and odors from textiles

One of the key advantages of laser cleaning for pet stain and odor removal is its ability to penetrate deep into the fibers of the textile. Unlike traditional cleaning methods that only address the surface level, laser cleaning can effectively reach the root of the problem, ensuring a thorough and long-lasting solution. This is particularly beneficial when dealing with pet stains, as they often seep deep into the fabric, making it challenging to completely eradicate them.

Furthermore, laser cleaning is a safe and eco-friendly alternative to conventional cleaning methods. It does not require the use of harsh chemicals or detergents, which can be harmful to both humans and pets. By harnessing the power of laser technology, this cleaning method eliminates the need for excessive water consumption, reducing the environmental impact associated with traditional cleaning processes. Additionally, laser cleaning leaves no residue behind, ensuring a clean and hygienic textile surface.

In addition to its effectiveness in removing pet stains and odors, laser cleaning also offers several other benefits. It can restore the original color and appearance of the textile, making it look as good as new. Laser cleaning can also eliminate allergens and bacteria that may be present in the fabric, promoting a healthier living environment for both humans and pets. Moreover, this method is gentle on delicate textiles, making it suitable for use on a wide range of materials, including carpets, upholstery, and clothing.

To ensure the best results, it is recommended to consult a professional laser cleaning service provider. These experts have the knowledge, experience, and specialized equipment required to effectively remove pet stains and odors from textiles. They can assess the severity of the problem and tailor the laser cleaning process accordingly, ensuring optimal outcomes.

In conclusion, laser cleaning has emerged as a game-changer in the realm of pet stain and odor removal from textiles. Its non-contact, non-abrasive, and chemical-free approach make it a safe and eco-friendly alternative to traditional cleaning methods. By harnessing the power of laser technology, this method can penetrate deep into the fabric, effectively eliminating pet stains and odors at their source. Additionally, laser cleaning offers numerous other benefits, including color restoration, allergen elimination, and gentle treatment of delicate textiles. So, if you’re struggling with pet stains and odors, consider opting for laser cleaning to restore your textiles to their pristine condition.

Keywords: laser cleaning, pet stains, odors, textiles, non-contact, non-abrasive, chemical-free, contaminants, vaporize, deep cleaning, eco-friendly, restoration, allergens, bacteria, professional service, color restoration, gentle treatment.

Long-tail phrases:

– Revolutionary laser cleaning method for pet stain removal from textiles

– Effective laser cleaning for eliminating pet odors from fabrics

– Non-abrasive and chemical-free laser cleaning for pet stain removal

– Thorough and long-lasting pet stain and odor removal with laser cleaning

– Eco-friendly and safe laser cleaning for pet stain and odor elimination

– Restoring textiles to their original condition with laser cleaning

– Laser cleaning: the ultimate solution for pet stain and odor removal

– Professional laser cleaning service for pet stain and odor elimination

– Laser cleaning: a gentle and effective method for pet stain removal

– Laser cleaning: the future of pet stain and odor removal from textiles.

Laser cleaning for removing dirt and stains from clothing and garments

One of the key advantages of laser cleaning is its ability to remove even the most stubborn stains, including oil, grease, ink, and wine stains. Unlike traditional cleaning methods, laser cleaning does not require the use of harsh chemicals or detergents, making it a safer and more sustainable option. It also eliminates the need for excessive water consumption, which is a significant environmental concern associated with traditional cleaning methods.

Another benefit of laser cleaning is its precision. The laser beam can be controlled to target specific areas, ensuring that only the dirt or stain is removed without affecting the surrounding fabric. This level of precision is particularly useful for delicate fabrics or garments with intricate designs, where traditional cleaning methods may cause damage.

Furthermore, laser cleaning is a time-efficient process. It can remove stains and dirt particles from clothing and garments in a matter of seconds, significantly reducing the cleaning time compared to traditional methods. This makes it an ideal solution for commercial textile cleaning operations, where time is of the essence.

In addition to its cleaning capabilities, laser technology also offers other advantages for the textile industry. For instance, laser cutting and engraving can be used to create intricate patterns and designs on fabrics, adding value and uniqueness to garments. Laser marking can also be used for labeling and branding purposes, providing a permanent and precise solution.

As with any technology, laser cleaning does have some limitations. It may not be suitable for all types of fabrics, particularly those that are highly reflective or heat-sensitive. Additionally, the initial investment in laser cleaning equipment can be costly, although the long-term benefits and cost savings may outweigh this initial expense.

In conclusion, laser cleaning is a highly efficient and eco-friendly solution for removing dirt and stains from clothing and garments. Its ability to remove even the most stubborn stains, precision, time-efficiency, and additional capabilities such as cutting and marking make it a valuable tool in the textile industry. As the demand for sustainable and effective cleaning methods continues to grow, laser cleaning is likely to become an increasingly popular choice.

Keywords: laser cleaning, dirt removal, stain removal, clothing, garments, textile industry, eco-friendly, laser ablation, stubborn stains, traditional cleaning methods, harsh chemicals, water consumption, precision, time-efficient, laser cutting, laser engraving, laser marking, fabric limitations, initial investment, cost savings, sustainable cleaning methods.

Long-tail phrases:

– Revolutionary technology in the textile industry

– Highly efficient and eco-friendly solution

– Traditional methods often fail to remove stubborn stains

– Laser ablation vaporizes dirt and stains without damaging fabric

– Removes oil, grease, ink, and wine stains

– Safer and more sustainable option than traditional cleaning methods

– Precision targeting without affecting surrounding fabric

– Time-efficient process for commercial textile cleaning operations

– Laser technology offers additional benefits such as cutting and marking

– Limitations on certain fabric types

– Initial investment in laser cleaning equipment

– Increasing demand for sustainable and effective cleaning methods.

Laser cleaning for removing dirt and stains from bed linens and pillowcases

The process of laser cleaning involves the use of a high-intensity laser beam that is directed towards the stained or dirty area of the fabric. The laser beam interacts with the contaminants, causing them to heat up and vaporize. As a result, the dirt and stains are effectively removed from the fabric, leaving it clean and refreshed. The laser can be adjusted to different power levels and frequencies, allowing for precise and controlled cleaning.

One of the major advantages of laser cleaning is its ability to remove even the most stubborn stains that traditional cleaning methods may struggle with. Whether it’s a coffee spill, ink mark, or food stain, the laser can target and eliminate the specific area of discoloration, restoring the fabric to its original state. Additionally, laser cleaning is a chemical-free process, making it an eco-friendly alternative to conventional cleaning methods that often rely on harsh detergents and solvents.

Another benefit of laser cleaning is its ability to reach deep into the fabric and remove dirt and contaminants that may be embedded within the fibers. This is particularly useful for bed linens and pillowcases, as they often come into contact with sweat, body oils, and dead skin cells that can accumulate over time. Laser cleaning can effectively penetrate the fabric and eliminate these impurities, ensuring a thorough and hygienic cleaning process.

Furthermore, laser cleaning is a gentle and non-destructive method that does not cause any damage to the fabric. Unlike traditional cleaning methods that may involve scrubbing or rubbing, laser cleaning does not put any mechanical stress on the material. This is especially important for delicate fabrics, such as silk or satin, which can easily be damaged by harsh cleaning techniques. With laser cleaning, the fabric remains intact and undamaged, prolonging its lifespan and maintaining its quality.

In addition to its cleaning capabilities, laser technology also offers other advantages for bed linens and pillowcases. For instance, laser cutting can be used to create intricate and decorative patterns on the fabric, adding a unique touch to the bedding. Laser engraving can also be employed to personalize the linens with monograms or logos, making them ideal for hotels or special occasions.

In conclusion, laser cleaning is a modern and innovative solution for removing dirt and stains from bed linens and pillowcases. Its non-contact and non-abrasive nature, along with its ability to target specific areas and penetrate deep into the fabric, make it an effective and efficient cleaning method. With its eco-friendly and gentle approach, laser cleaning ensures hygienic and long-lasting bedding. So, say goodbye to stubborn stains and hello to fresh and clean linens with the power of laser technology.

Keywords: laser cleaning, dirt removal, stain removal, bed linens, pillowcases, hygiene, laser technology, textile industry, non-contact, non-abrasive, contaminants, high-intensity laser beam, vaporize, precise cleaning, stubborn stains, eco-friendly, chemical-free, deep cleaning, gentle, non-destructive, fabric damage, prolong lifespan, laser cutting, laser engraving, personalized linens.

Long-tail phrases: laser cleaning for removing dirt from bed linens, laser cleaning for removing stains from pillowcases, innovative solution for cleaning bed linens, non-contact method for removing dirt from fabrics, eco-friendly cleaning method for bed linens, laser technology for deep cleaning of pillowcases, gentle and non-destructive cleaning for bed linens, laser cutting for decorative patterns on fabrics, laser engraving for personalized linens.

Laser cleaning for removing dirt and stains from automotive textiles

Laser cleaning is a non-contact and non-abrasive cleaning method that utilizes the power of laser beams to remove contaminants from various surfaces. It involves the use of a high-intensity laser beam that is directed towards the textile surface, causing the contaminants to vaporize or disintegrate. The laser beam selectively targets the dirt and stains, leaving the textile material unharmed. This process is highly precise and can be controlled to remove even the most stubborn stains without damaging the fabric.

Benefits of Laser Cleaning for Automotive Textiles:

1. Efficiency: Laser cleaning offers a highly efficient cleaning solution, as it can remove dirt and stains from automotive textiles in a fraction of the time compared to traditional methods. The laser beam can cover a large surface area quickly, resulting in significant time savings.

2. Eco-friendly: Unlike traditional cleaning methods that often involve the use of harsh chemicals, laser cleaning is an environmentally friendly option. It does not require the use of any chemicals or solvents, reducing the risk of harmful residues being left behind. Additionally, laser cleaning produces minimal waste, making it a sustainable choice for automotive textile cleaning.

3. Preservation of textile properties: Laser cleaning is a gentle process that does not damage the textile material. It selectively targets the contaminants, leaving the fabric intact. This ensures that the original properties of the textile, such as color, texture, and softness, are preserved after the cleaning process.

4. Versatility: Laser cleaning can be used on a wide range of automotive textiles, including car seats, carpets, headliners, and door panels. It is effective in removing various types of stains, including oil, grease, ink, and food stains. This versatility makes laser cleaning a valuable tool for automotive manufacturers, car detailing businesses, and car owners.

5. Cost-effective: While the initial investment in laser cleaning equipment may be higher compared to traditional cleaning methods, the long-term cost benefits are significant. Laser cleaning eliminates the need for expensive cleaning agents and reduces labor costs due to its efficiency. Moreover, the extended lifespan of automotive textiles resulting from laser cleaning can lead to cost savings in the long run.

Conclusion:

Laser cleaning has revolutionized the automotive textile cleaning industry by offering a highly efficient, eco-friendly, and versatile solution for removing dirt and stains. Its ability to preserve the textile properties and cost-effectiveness make it an attractive option for automotive manufacturers and car owners alike. As the demand for sustainable and efficient cleaning methods continues to grow, laser cleaning is expected to play a pivotal role in maintaining the cleanliness and aesthetics of automotive textiles.

Keywords: laser cleaning, automotive textiles, dirt removal, stain removal, eco-friendly cleaning, textile preservation, cost-effective cleaning

Long-tail phrases: laser cleaning for automotive textiles, removing dirt and stains from automotive textiles, benefits of laser cleaning for automotive textiles, eco-friendly cleaning for automotive textiles, preserving textile properties with laser cleaning, cost-effective cleaning for automotive textiles.

- Laser cleaning for removing contaminants from optical lenses - 22 April 2024

- Where do the differences in project valuation come from? - 22 April 2024

- Laser cleaning for removing dirt and stains from textiles - 29 January 2024